If you’re exploring options for geotextiles, understanding the differences between short filament and filament geotextiles can significantly impact your project’s success. We’re here to clarify these distinctions and help guide your choices.

Short filament geotextiles, made from bonded short fibers, are ideal for filtration and separation tasks in construction, while filament geotextiles, crafted from continuous fibers, are better suited for reinforcement and stabilization due to their higher tensile strength.

Stay tuned as we dive deeper into each type’s specific benefits and applications, helping you make an informed decision for your needs.

Understanding Geotextiles: Short Filament vs. Filament

Geotextiles are essential components in civil engineering, landscaping, and construction projects. They play a critical role in soil stabilization, erosion control, and water filtration. The primary difference between short filament and filament geotextiles lies in their fiber composition and manufacturing process.

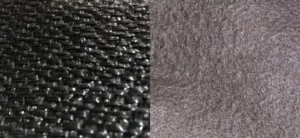

Short filament geotextiles are made from short synthetic fibers, such as polyester or polypropylene, that are randomly distributed and needle-punched or heat-bonded. This type of geotextile is highly porous, making it ideal for filtration, as it allows water to pass through while preventing soil particles from moving. It’s commonly used in drainage applications, road construction, and erosion control projects.

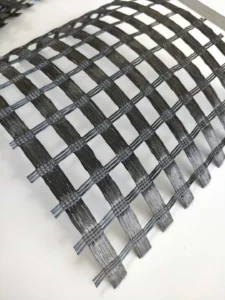

Filament geotextile, on the other hand, is produced from continuous synthetic fibers that are woven or non-woven to form a robust fabric. These geotextiles are less porous and have high tensile strength, making them suitable for reinforcement purposes. They are extensively used in retaining wall construction, embankment stabilization, and roadbed reinforcement.

Appearance Distinctions

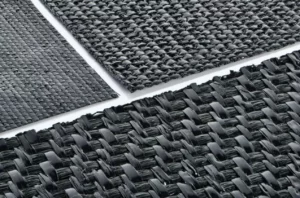

Short-filament and filament geotextiles are distinguishable at a glance. Filament geotextiles exhibit longer surface fibers, often appearing whiter compared to the darker hues of short-filament geotextiles.

Material Composition and Strength Characteristics

Filament geotextiles typically employ filament spunbond needle-punched nonwovens composed of polyester fibers, offering superior strength, elongation, and bursting parameters compared to short-filament geotextiles. Conversely, short-filament geotextiles, typically made from polyester or polypropylene staple fibers, exhibit different strength and elongation characteristics compared to filament geotextiles of equivalent specifications.

Hydraulic and Mechanical Properties

Filament geotextiles tend to be thicker, allowing for the formation of three-dimensional voids, which can enhance hydraulic functions. They also demonstrate better puncture resistance compared to short-filament geotextiles. Additionally, filament geotextiles exhibit superior creep resistance when compared to their short-filament counterparts with the same mass per unit area.

Engineering Applications

Short-Filament Geotextile Applications:

- Reinforcement and Stabilization: Primarily utilized for macro-reinforcement in various projects.

- Filtration and Drainage: Replaces traditional materials for infiltration and drainage layers.

- Barrier Functions: Helps in separating materials of different particle sizes, ensuring structural stability.

- Protective Applications: Used in slope protection, urban greening, and crack prevention in roads.

Filament Geotextile Applications:

- Water Conservancy Projects: Employed for reverse filtration, slope protection, and channel isolation.

- Infrastructure Construction: Utilized for foundation isolation, reinforcement of soil slopes, and drainage in various transportation projects.

- Port Engineering: Applied in soft foundation treatment, reinforcement, and drainage of port structures.

- General Construction: Employed in diverse construction projects owing to its versatility.

Performance Indicators and Cost Comparison

Filament geotextiles typically exhibit higher breaking strength and other performance indicators compared to short-filament geotextiles. Consequently, filament geotextiles often command a higher price compared to their short-filament counterparts of equivalent specifications.

In conclusion, both filament and short-filament geotextiles serve crucial roles in reinforcing and protecting engineering projects. The choice between the two depends on specific project requirements and conditions. For detailed application guidance and tailored solutions, reach out to us for expert advice or request free geotextile samples!

Geotextile Application Fields

Geotextiles find extensive application in various engineering scenarios:

- Retaining Walls: Reinforcement in backfilling and anchoring retaining walls.

- Road Construction: Stabilization of flexible pavements and prevention of crack reflection.

- Slope Stabilization: Enhancing stability of gravel slopes and preventing soil erosion.

- Subgrade Isolation: Creating isolation layers between road ballast and subgrade.

- Water Conservancy: Infiltration and drainage in dams, channels, and embankments.

- Infrastructure Projects: Strengthening weak foundations in roads, railways, and airports.